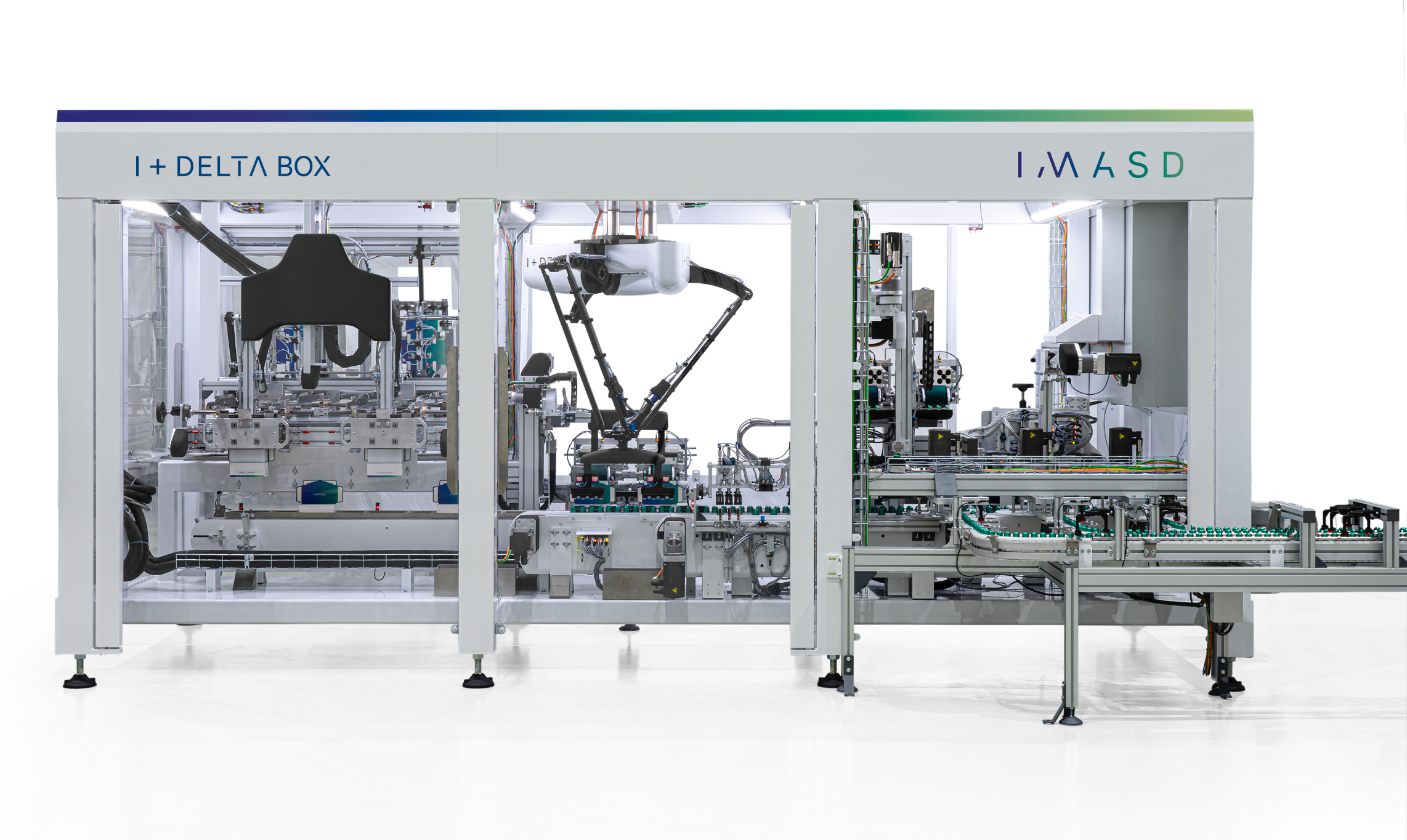

I+DELTA BOX

Machine for boxing coffee capsules compatible with Nespresso® and Dolce Gusto® coffee machines.

I+DELTA BOX,

modular and adaptable

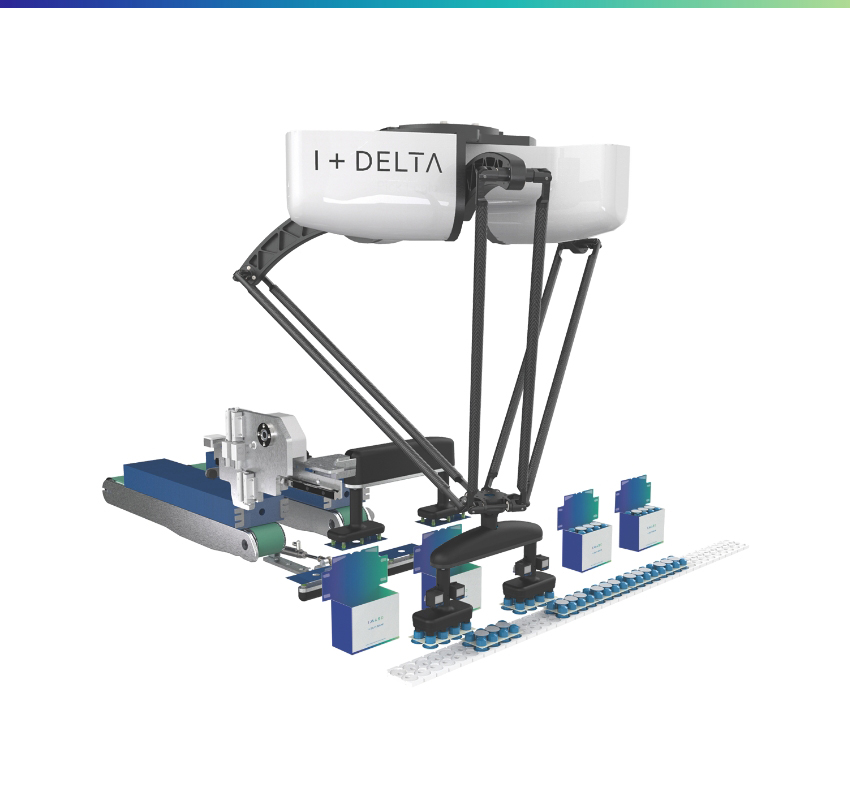

Machine for boxing coffee capsules with I+Delta Robot, compatible with coffee capsules from Nespresso® (I+Delta Box – NP) and Dolce Gusto® (I+Delta Box – DG).

Specifically developed to box capsules in aluminium, compostable and plastic; providing versatility with 3 types of boxes in different formats.

ONE MACHINE,

MULTIPLE SOLUTIONS

Compatible with different capsules and box formats.

I+Delta Box is designed to work with aluminium, compostable and plastic capsules.

BOXING UP TO 400 CAPSULES/MIN

NP ONE & NP DUO

CONFIGURE YOUR

I+DELTA BOX

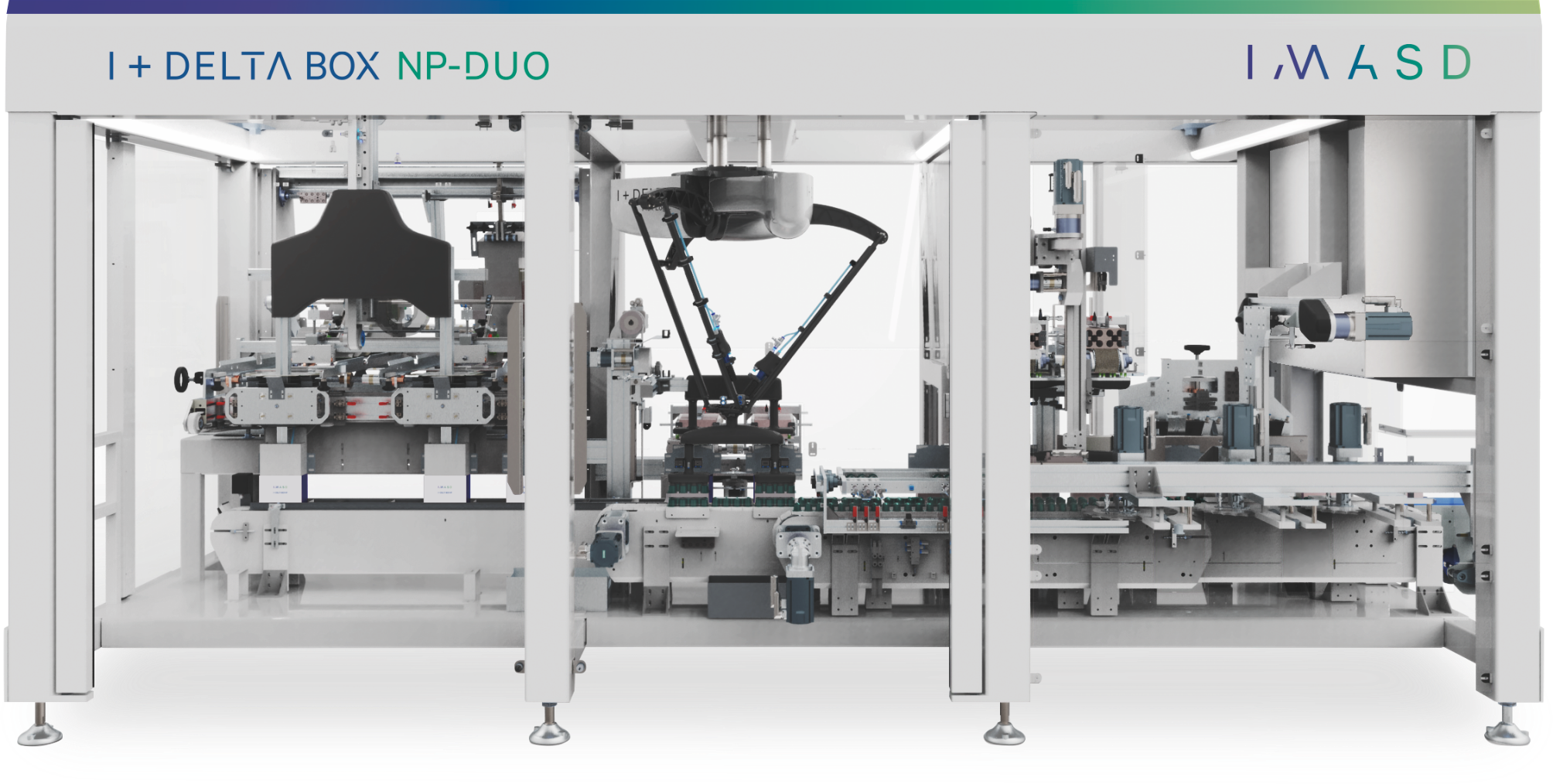

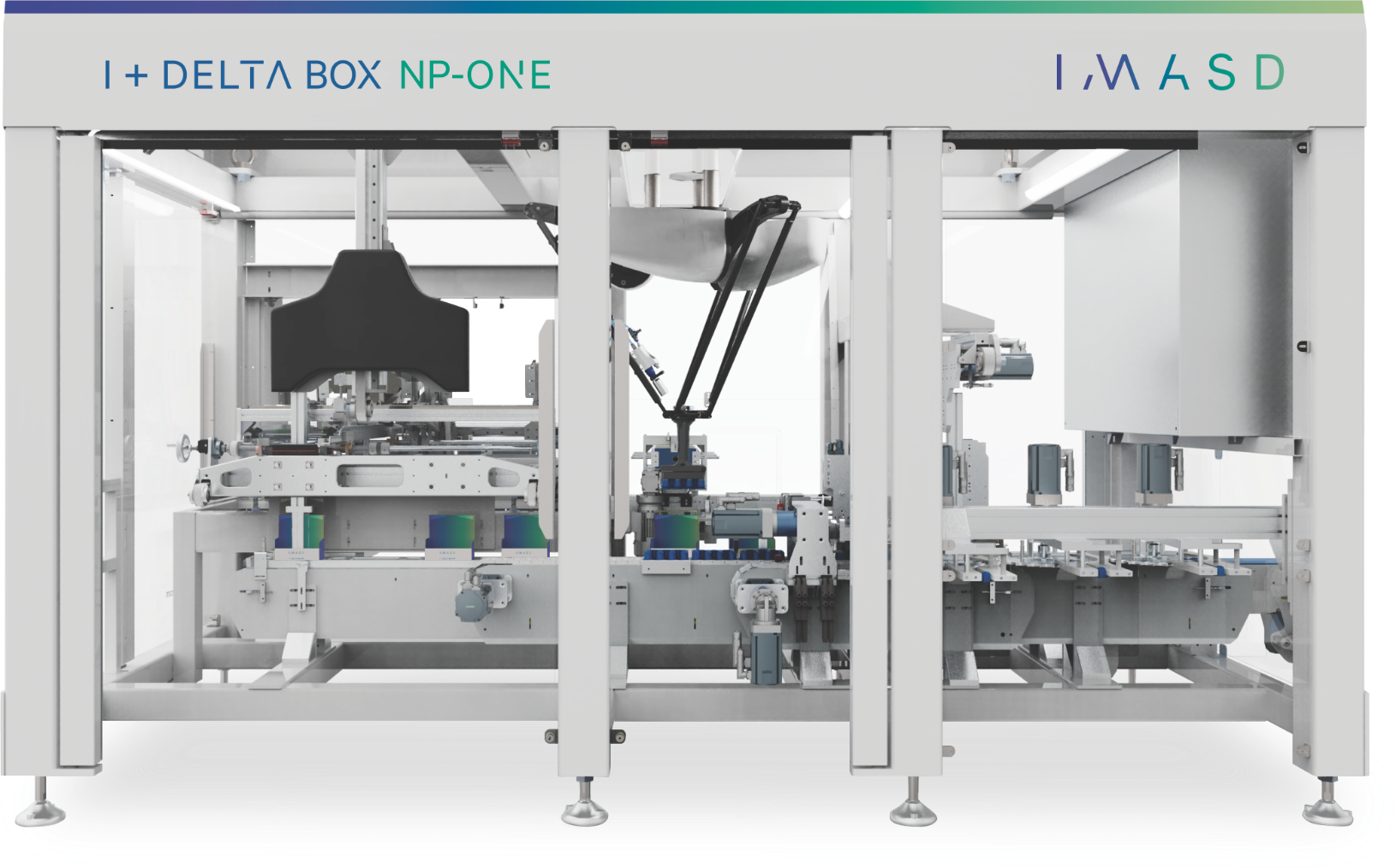

Adapt I+Delta Box – NP to your packing, appearance and production pace needs with the NP ONE and NP DUO models.

| ROBOT DELTA | DELTA ROBOT + INTERLAYER ROBOT | |

| Case 10/11 | 200 CAPSULES/MIN. | 200 CAPSULES/MIN. |

| Case 20/22 | 200 CAPSULES/MIN. | 200 CAPSULES/MIN. |

| Case 30/33 | 155 CAPSULES/MIN. | 200 CAPSULES/MIN. |

| Case 40/44 | 155 CAPSULES/MIN. | 200 CAPSULES/MIN. |

| DELTA ROBOT | DELTA ROBOT + INTERLAYER ROBOT | |

| Case 10/11 | 400 CAPSULES/MIN. | 400 CAPSULES/MIN. |

| Case 20/22 | 400 CAPSULES/MIN. | 400 CAPSULES/MIN. |

| Case 30/33 | 310 CAPSULES/MIN. | 400 CAPSULES/MIN. |

| Case 40/44 | 310 CAPSULES/MIN. | 400 CAPSULES/MIN. |

Define your box types according to your preferred perimetral flap, closure type and number of levels. The type of case does not influence the production of the machine.

BOX A

BOX A+B

BOX A+B+C

We achieve the perfect pattern and appearance of the capsules inside the case with Honey-Comb Robot.

Or increase production in the I+Delta Box – NP by placing the divider between layers and synchronising the I+Delta Robot with the Interlayer Robot.

HONEY-COMB ROBOT

INTERLAYER ROBOT

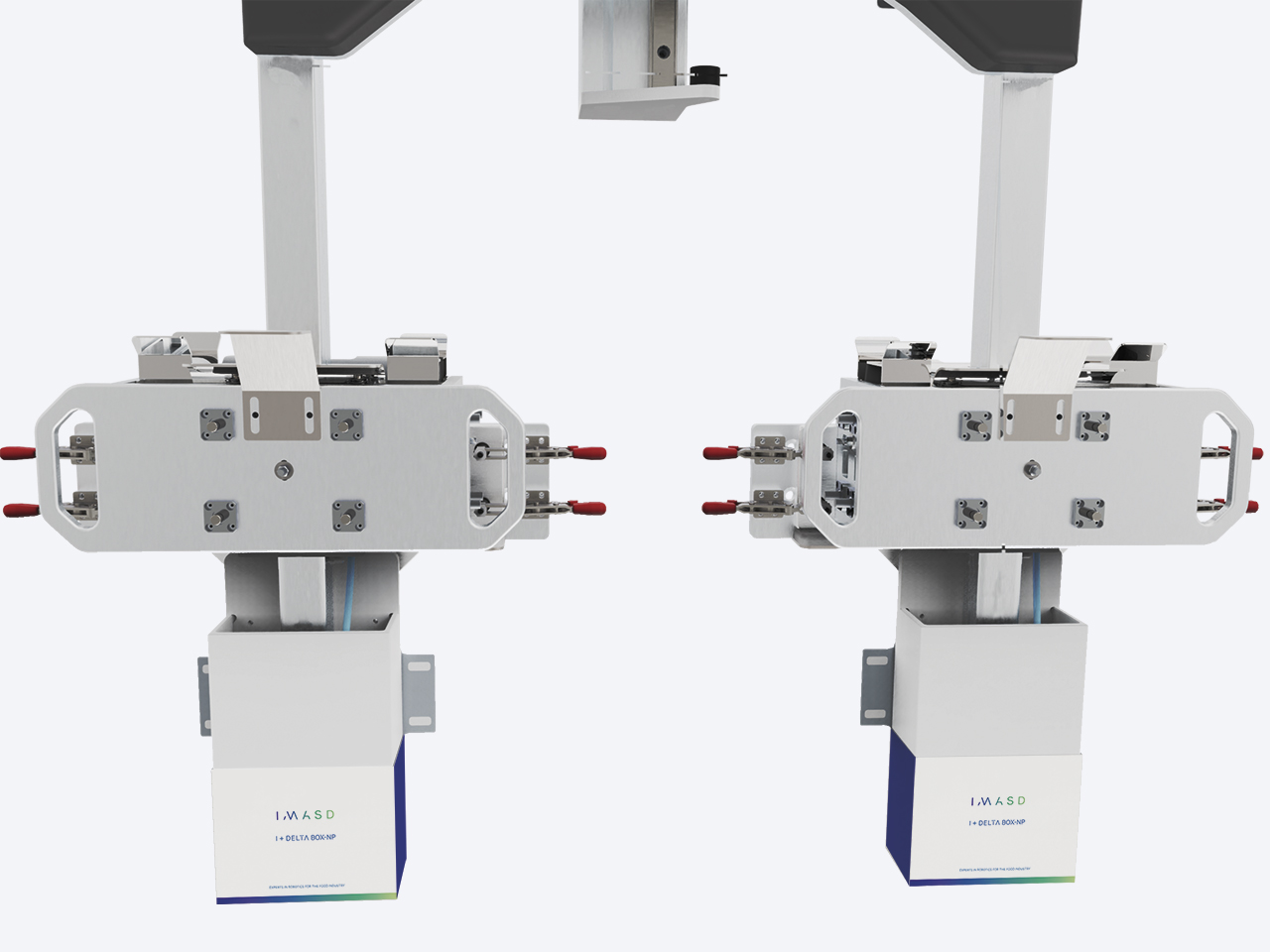

INTERLAYER DISPENSER DUO

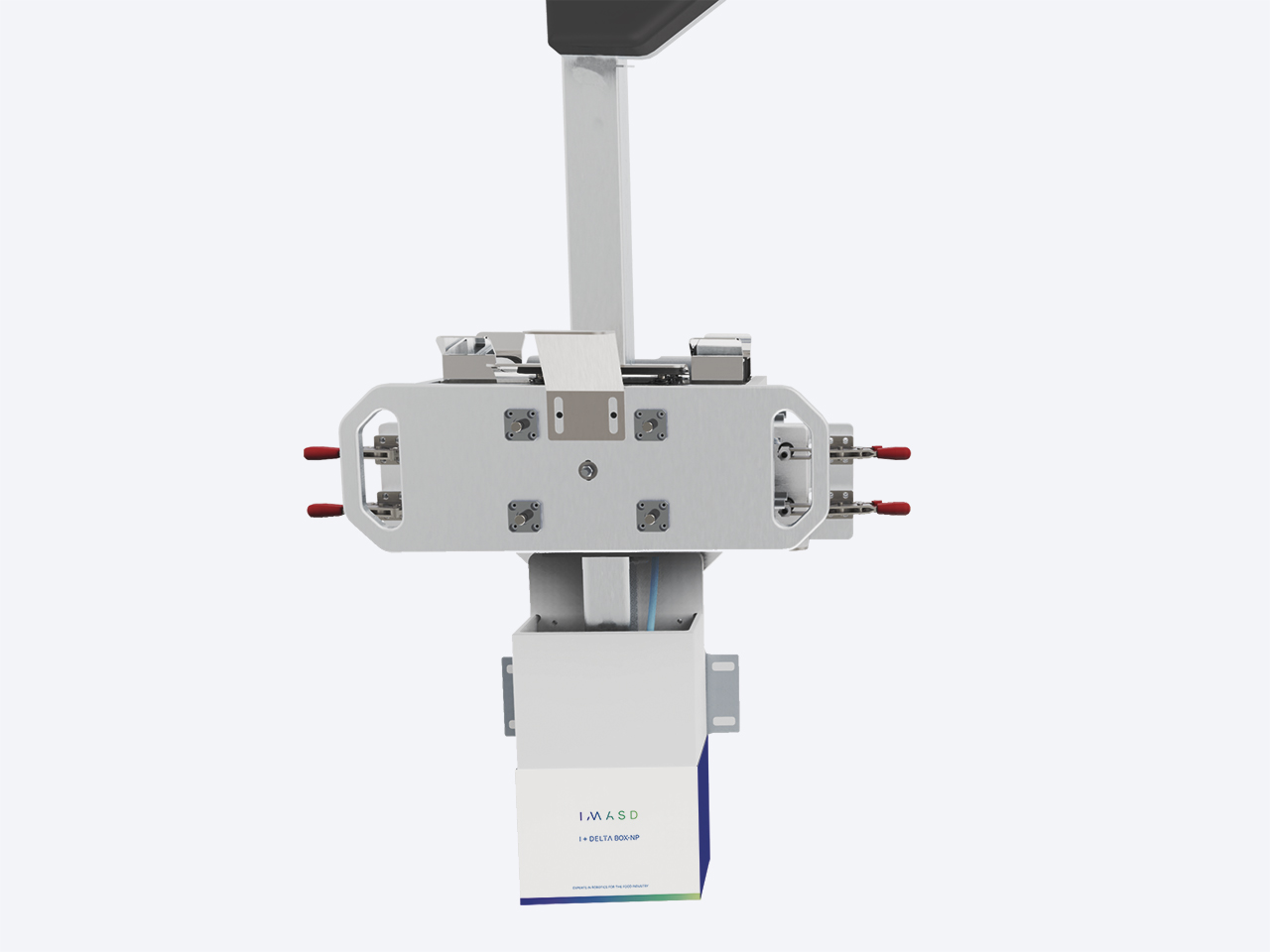

INTERLAYER DISPENSER ONE

BOX ERECTOR DUO

BOX ERECTOR ONE

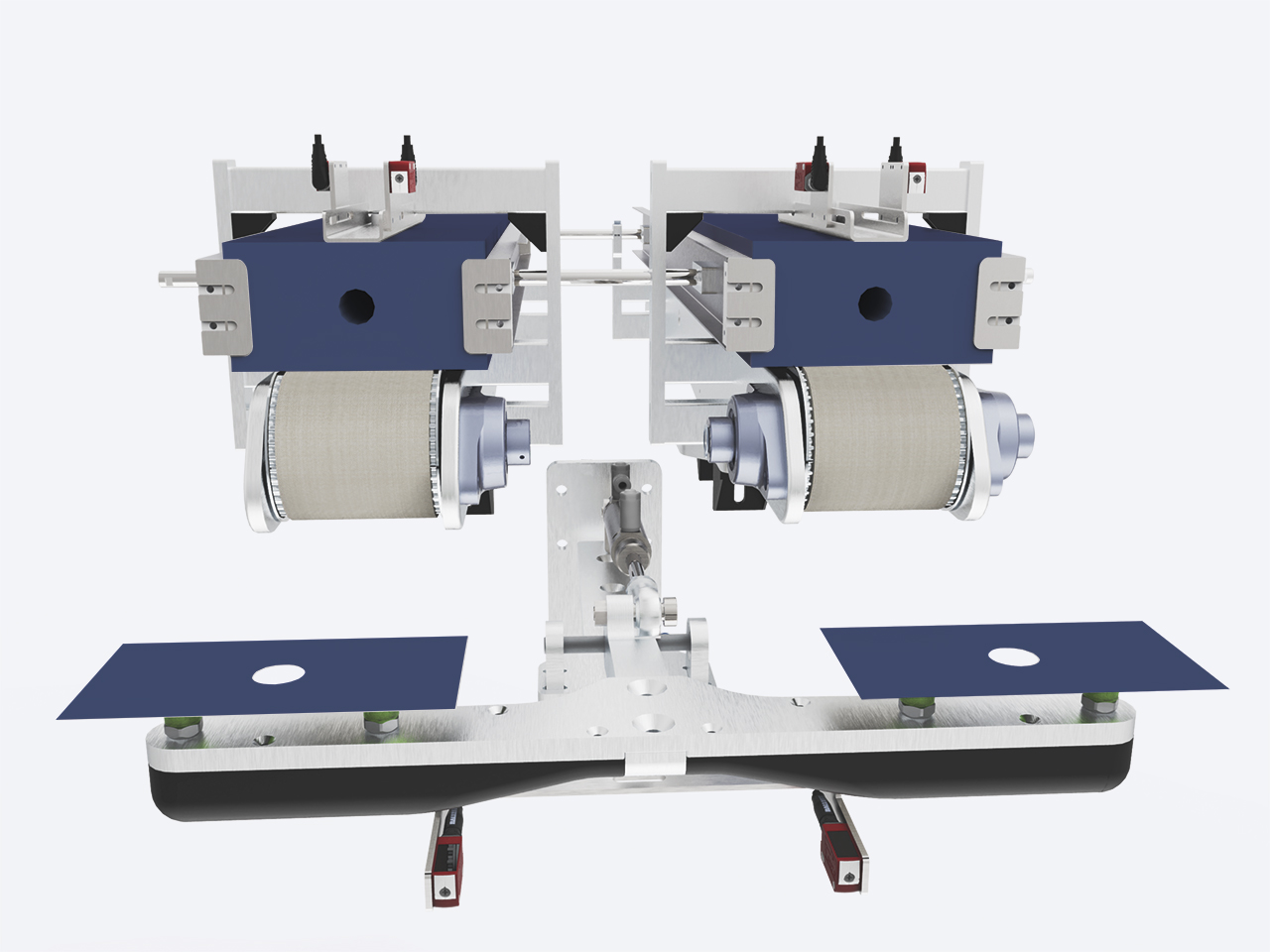

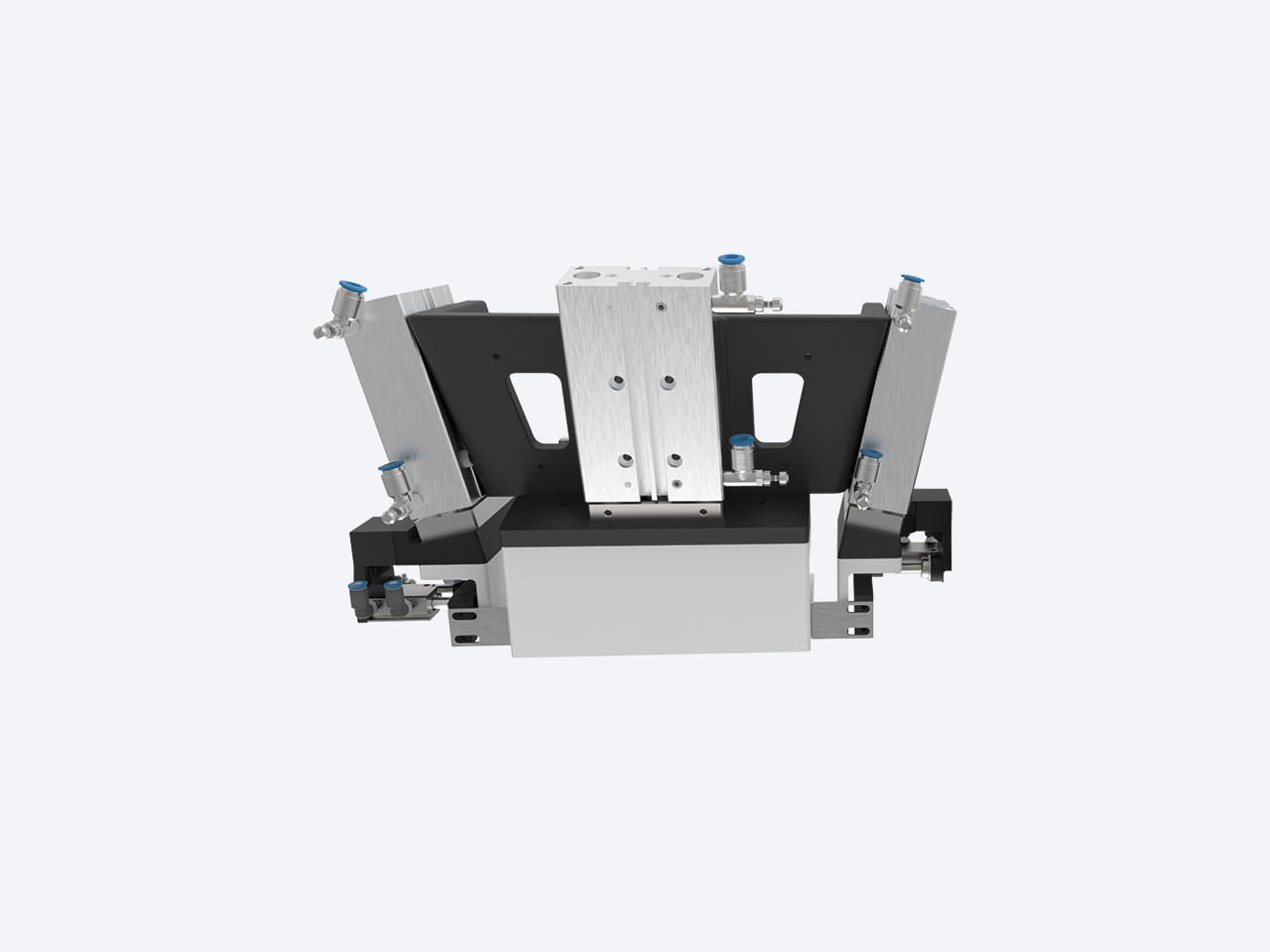

I+DELTA BOX GRIPPER DUO

I+DELTA BOX GRIPPER ONE

BOX CLOSER DUO

BOX CLOSER ONE

WE TAKE CARE

OF YOUR CAPSULES

I+Delta Box is designed to handling with care your aluminium, compostable and plastic Nespresso® and Dolce Gusto® coffee capsules.

Soft handling

The technology integrated into the modules of capsule infeeding, distribution and individual indexing offers a smooth handling that guarantees the careful manipulation of the outer surface of the capsules.

Intacted seal

Our robot’s grip is specifically designed to provide a careful capsule handling, protecting the capsule’s top and bottom seal.

Variety of capsule types

The technology integrated into our robotic module offers the versatility to work with aluminium, compostable and plastic capsules, as well as adaptability to the different capsule types.

Attractive Presentation - Honeycomb

Steady capsules arrangement through a honeycomb carton, which provides stability, protection and a good presentation of the capsules inside the box.

COMPATIBLE WITH THREE BOXES TYPES

I+Delta Box is designed to create three types of cases according to needs regarding protection, ease in closing and accessibility of the capsules.

BOX TYPE A

With easy access to the capsules, it offers an easy-close system for the consumer while keeping the capsules protected.

BOX TYPE B

Designed to ensure highly

protected capsules thanks to outer protection system. Features an easy-close system, making it uncomplicated and facilitating use for the consumer.

BOX TYPE C

Inscrutable capsule protection, built in with an extra easy opening and closing system that enables a comfortable access to the capsules.

BOX CONFIGURATION

I+Delta Box-NP allow to box capsules in different packaging types and formats, adapting to customer needs.

INTERLAYER

Provides steadiness to different heights within the box, protecting the capsules and allowing a tidy presentation.

SEPARATING HONEYCOMB

Avoids contact between capsules, improving the product

presentation and protecting its surface.

4 FORMATS

I+Delta Box is capable of box between 10 and 44 capsules per case, compatible with models of different capacities distributed over various layers.

Box 10/11 units

Box 20/22 units

Box 30/33 units

Box 40/44 units

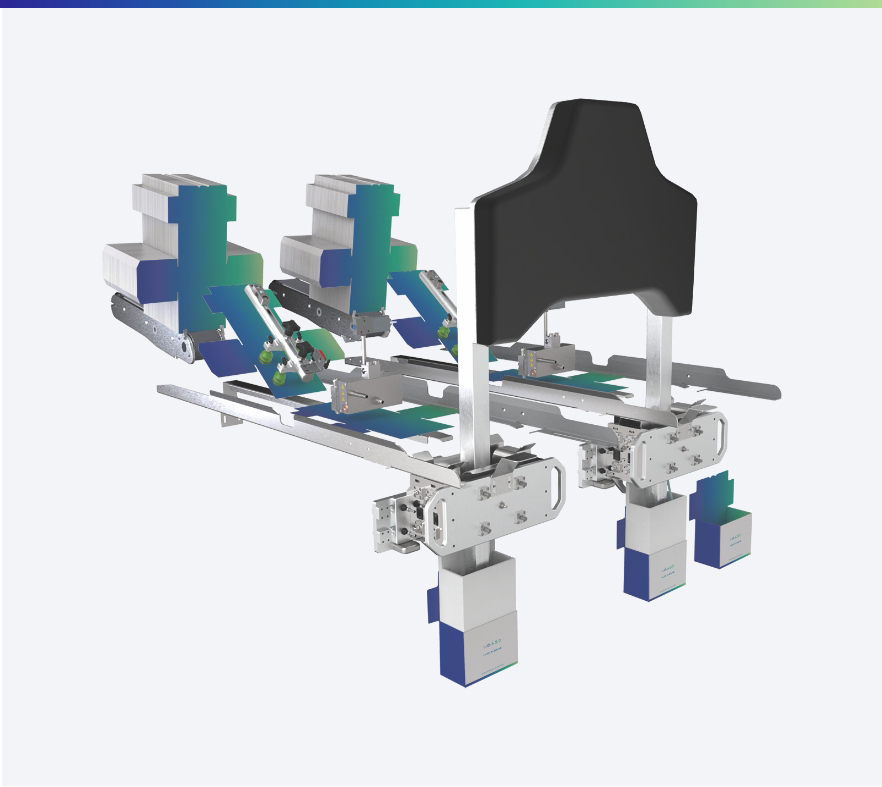

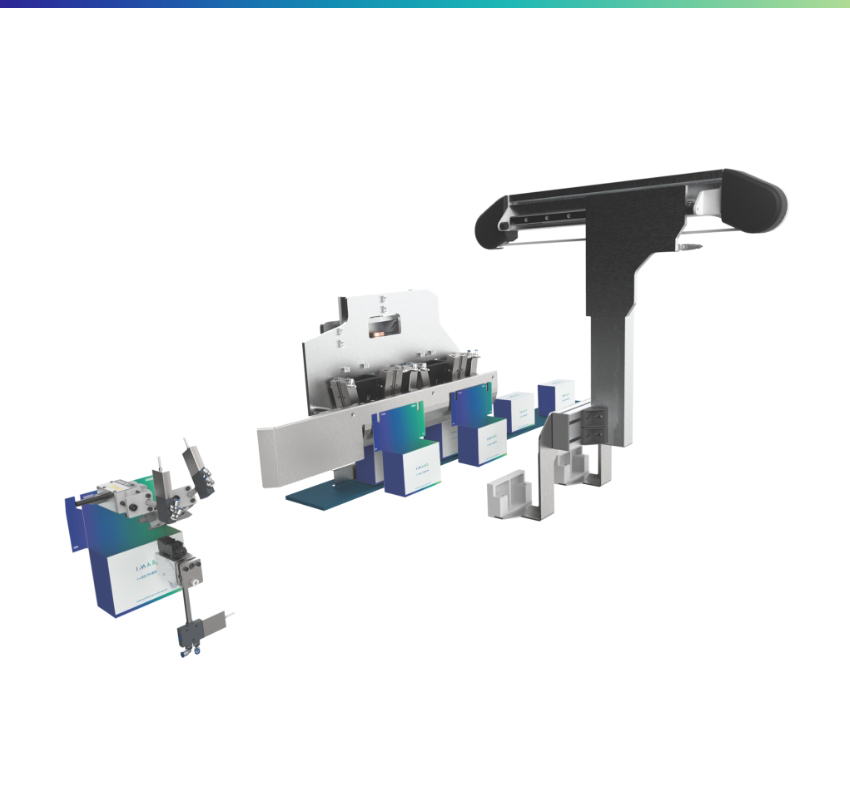

I+DELTA BOX’S MODULES

From case erecting to the final close of the boxes, I+Delta Box manages every process of box packing coffee capsules, improving efficiency thanks to the integration and synchronisation of modules.

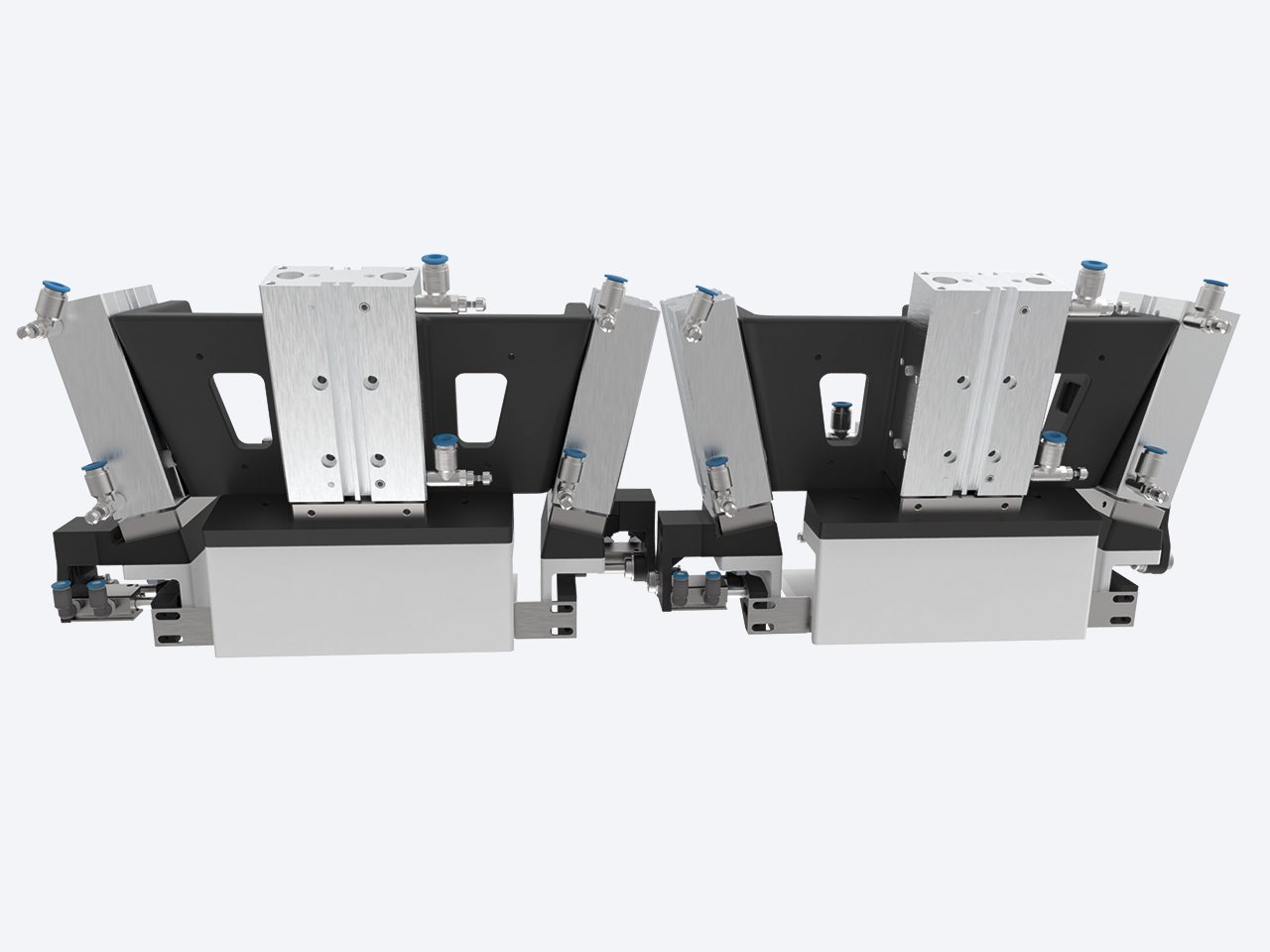

Box erector

module

Erects boxes with different capacities.

AUTONOMY

Up to 60 minutesof autonomy dispensing cardboard plates.

QUALITY AND ACCURACY

High accuracy in the placement of the cardboard plates and glue application points.

AGILITY

Speed and simplicity for format

changing (tool-free).

TOTAL CONTROL

Control in the erection, finish and delivery of boxes thanks to its servocontrolled engines.

Capsules

handling

Counts, inserts capsules and verifies full case.

I+DELTA ROBOT

Inserts and ensures the presence of all capsules in the box through a system of capsule presence control and verification, checking each layer of full boxes.

INTERLAYER ROBOT

Increases the cadence of the I+Delta Box-NP, as it places interlayer cardboards in a synchronised work with the robot I+Delta.

SOFT AND ACCURATE HANDLING

Our I+Delta Robot gripper is specifically designed to carry out a soft and precise capsule handling that guarantees care with the outer finishing of the capsules.

FLEXIBILITY

Flexibility and total control in the capsules pick and place

within the box. Insertion of mosaics of 10/11 capsules per

level, up to 4 levels (I+Delta Robot).

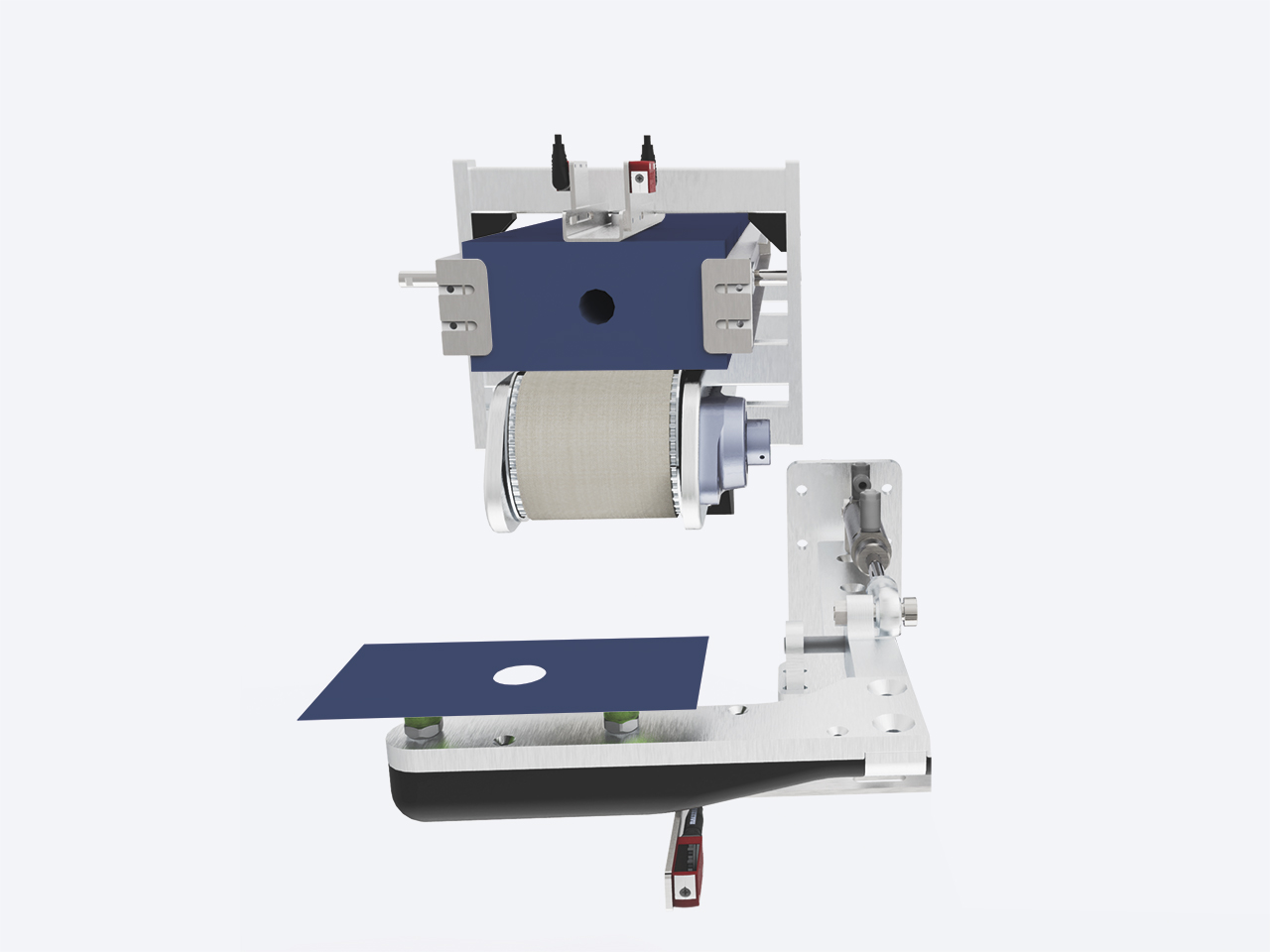

Mosaic

formation

Quality control and formation of honeycomb mosaic.

HONEYCOMB

Improves the in-box care and presentation. Honeycomb Placement / Insertion, (cartesian robot).

CAPSULE FLIPPING SYSTEM

Capsules are placed upside down to complete the mosaic, which can be controlled from the screen (allows the third capsule to be rotated upside down).

MOSAIC SENSOR BRIDGE

Performs a first quality check point to assure mosaic completeness, prior to the capsules´ arrival to the robot.

OPERATION EFFICIENCY

Equal distribution between rails thanks to the capsule flow control system.

Box closing

module

Control system for closure in

different box types and formats.

EFFICIENCY

Quick and easy format changes (without tools) in an estimated 10 minutes.

QUALITY CONTROL

Ensured reliability thanks to the machine’s integrated system that discards and controls consistency in the full case.

IMPENETRABILITY

Maximum quality in the box closure, thanks to control and accuracy provided by servocontrolled engines.

SEALING

High accuracy in the application of glue in the

box, for its subsequent closure.

I+DELTA BOX, THE MACHINE

FOR BOXING COFFEE CAPSULES

For more information about the I+Delta Box machine or if you require a customised quote according to your needs, please contact us.